Descriptions

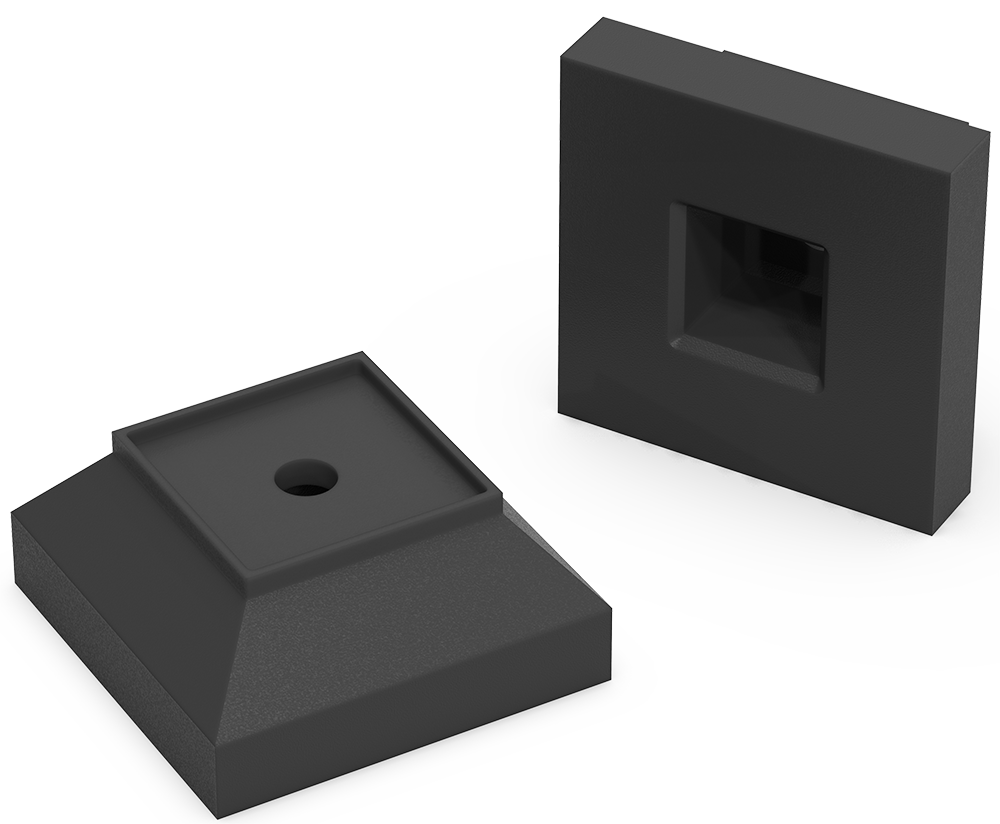

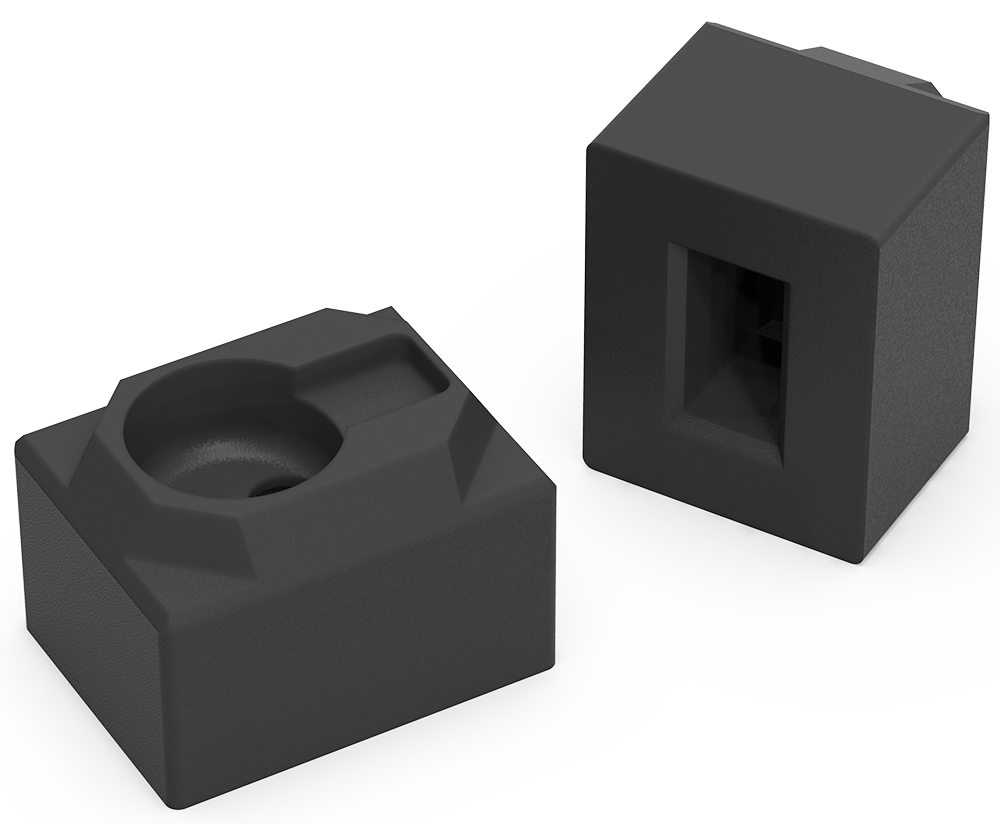

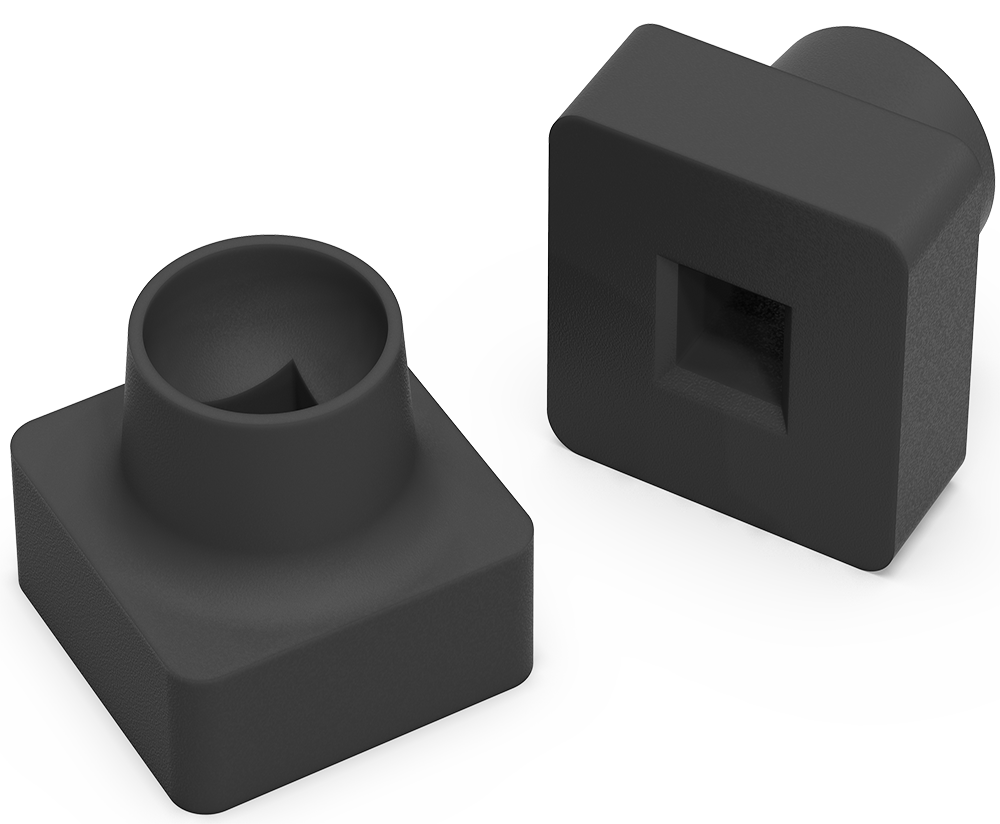

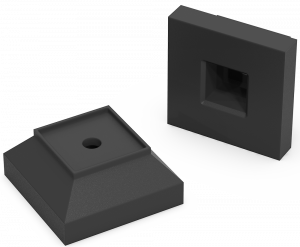

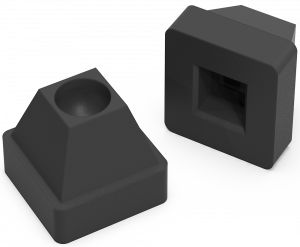

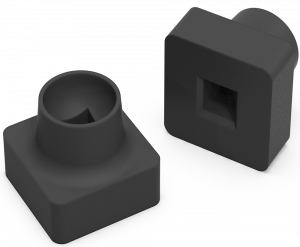

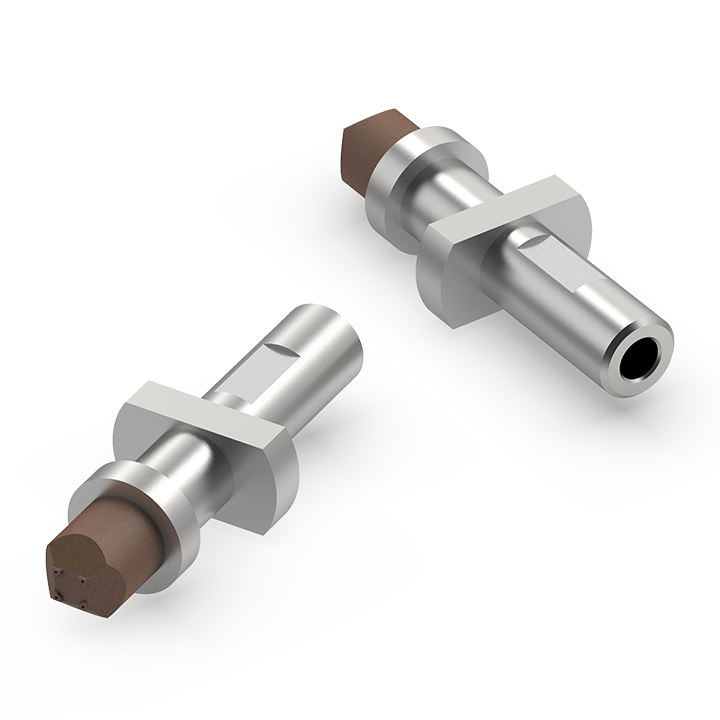

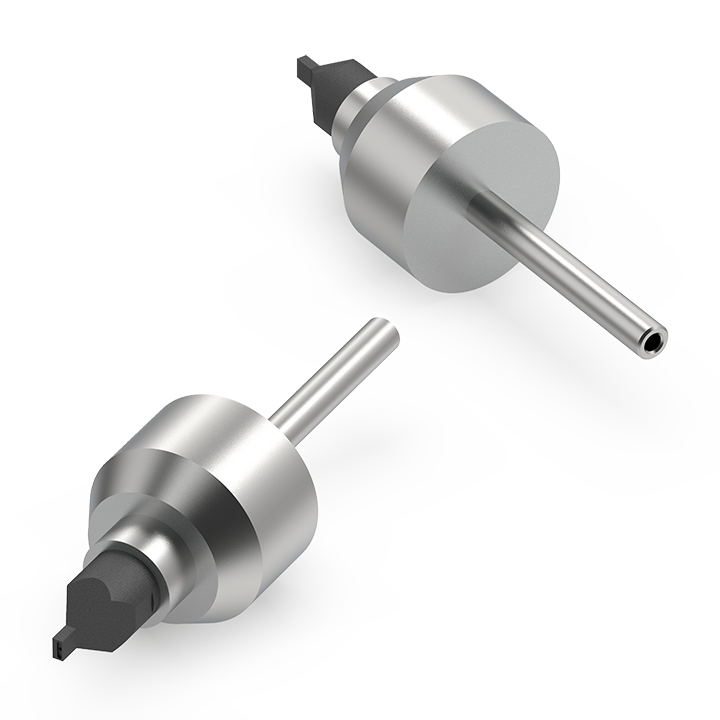

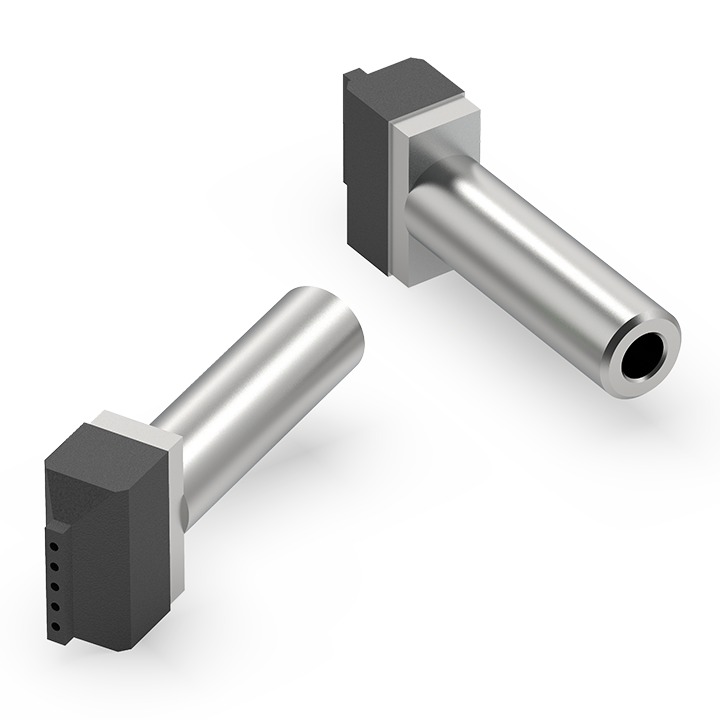

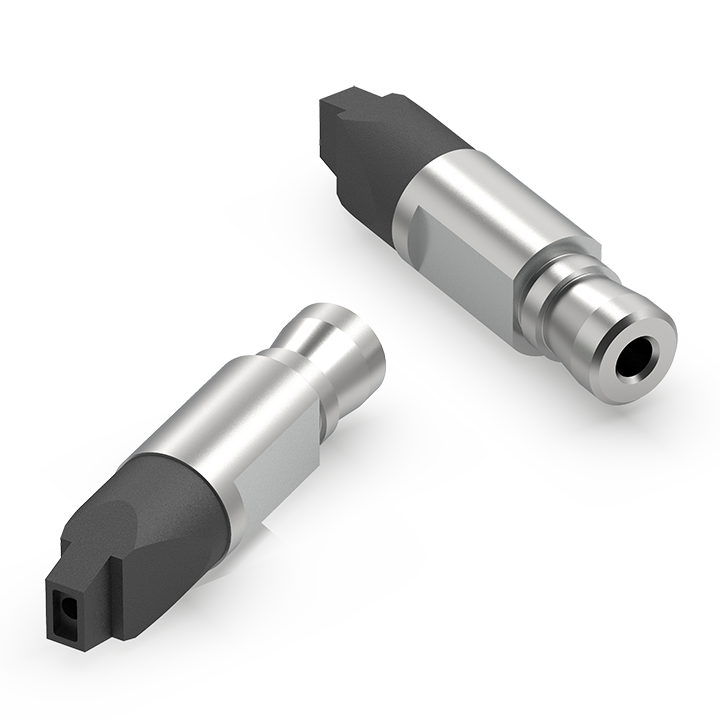

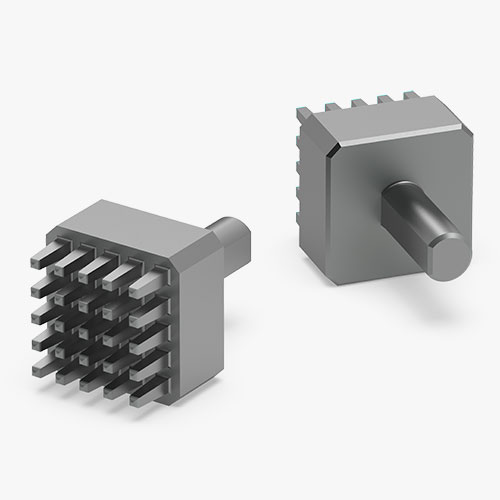

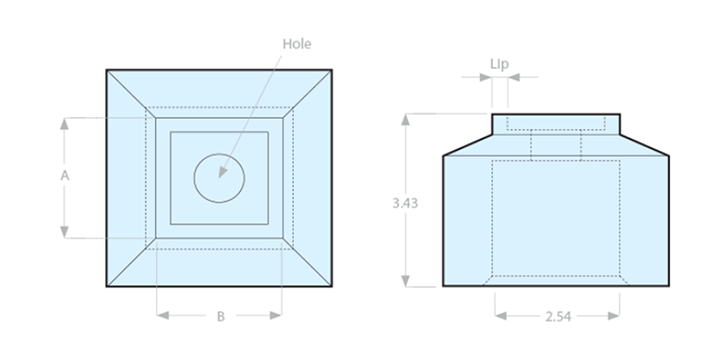

Vacuum Relief Tips are designed to avoid profiles or protrusions on your dies and devices, with a high degree of customization available. The design of our Vacuum Relief Tips feature a pocketed opening on the surface of the tip, which creates a reservoir of air to enhance the vacuum suction force during application.

Orcus manufactures a wide range of standard Vacuum Relief Tip sizes for common applications and die sizes. Customized tip sizes featuring thin walls designs (≥0.15mm wall thickness) with central, offset and spherical relief configurations can be designed and manufactured for your specific application.

Features

- Reduced contact surface area between the tip and the die while not sacrificing suction force

- Suitable for use with our Traditional, Tri-Lock, Compression and Magnetic Holders

- Available in NBR, HPR, UPR and CR Rubber Materials

- 50-90 Shore A Hardness levels to cater to wide range of applications

- E6-E9 Static Dissipative properties to ensure proper Electrostatic Discharge

- Can be made in Round, Square, Rectangular and Custom outer profiles with different pocket designs

- Options available between Box Reliefs or Spherical Reliefs depending on the level of rigidity required for the tip structure

Benefits

- Compared to the Flat Tip design, Vacuum Relief Tip designs allows for stronger vacuum force to be applied to the die or device

- Reduced level of die or device rotation due to insufficient suction

- Reduced sticky die effect for swift Pick and Place motion

- Tailor made pocket sizes for the avoidance of sensitive bumps, profiles or protrusions of your die and device

Material Information

All our rubber compounds are entirely developed in-house by our Material Science R&D team. These compounds are developed with the latest innovations in rubber technology and feature formulations that are designed specially for use in the Semiconductor industry. Extra pure formulations that leave no marks on die, wide range of Shore A hardnesses, Static Dissipative properties, long tool life and full RoHS & REACH compliance are the hallmarks of our rubber compounds.

| Material Description | Hardness | Surface Resistivity (ESD) | Static Dissipation Period (s) | Continuous Working Temperature °C |

|---|---|---|---|---|

| NBR | Shore A 75-80 | Static Dissipative (E6 to E9) | 0.02 to 0.03 | 130 |

| NBR (Soft) | Shore A 50-55 | Static Dissipative (E6 to E9) | 0.02 to 0.03 | 130 |

| NBR (Hard) | Shore A 85-90 | Static Dissipative (E6 to E9) | 0.02 to 0.03 | 130 |

| NBR (Coated) | Shore A 75-80 | Static Dissipative (E6 to E9) | 0.02 to 0.03 | 150 |

| HPR | Shore A 75-80 | Static Dissipative (E6 to E9) | 0.01 to 0.02 | 260 |

| HPR (Soft) | Shore A 50-55 | Static Dissipative (E6 to E9) | 0.01 to 0.02 | 260 |

| HPR (Hard) | Shore A 85-90 | Static Dissipative (E6 to E9) | 0.01 to 0.02 | 285 |

| UPR | Shore A 75-80 | Static Dissipative (E6 to E9) | 0.01 to 0.02 | 400 |

| CR (ESD) | Shore A 75-80 | Static Dissipative (E6 to E9) | 0.03-0.04 | 120 |

| CR | Shore A 75-80 | Insulative (>E10) | 0.03-0.04 | 120 |

Product Information

Standard Vacuum Relief Rubber Tips

| Part Number | Dimensions "X" | Dimensions "Y" | Height | Wall Thickness |

|---|---|---|---|---|

| RMC-NAFT-01000100-1 | 1 | 2 | 3 | 4 |

| RMC-NAFT-01000100-2 | 2 | 3 | 4 | 5 |

| RMC-NAFT-01000100-3 | 3 | 4 | 5 | 6 |

| RMC-NAFT-01000100-4 | 4 | 5 | 6 | 7 |

| RMC-NAFT-01000100-5 | 5 | 6 | 7 | 8 |

| RMC-NAFT-01000100-6 | 6 | 7 | 8 | 9 |

| RMC-NAFT-01000100-7 | 7 | 8 | 9 | 10 |

| RMC-NAFT-01000100-8 | 8 | 9 | 10 | 11 |

| RMC-NAFT-01000100-9 | 9 | 10 | 11 | 12 |

Customized Vacuum Relief Rubber

If you are unable to find a size that fits your application from our catalog, get in touch with us and our Application Experts will provide you with a customized turnkey solution according to your die size, process and application.

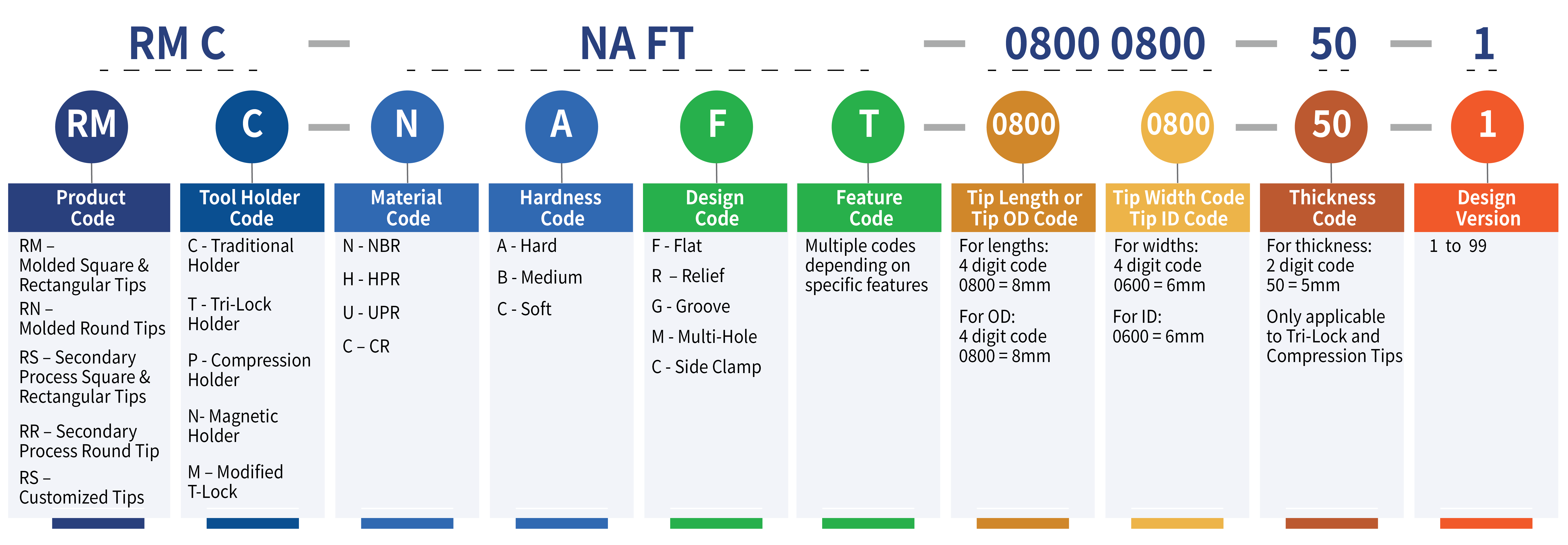

Part Numbers And Ordering